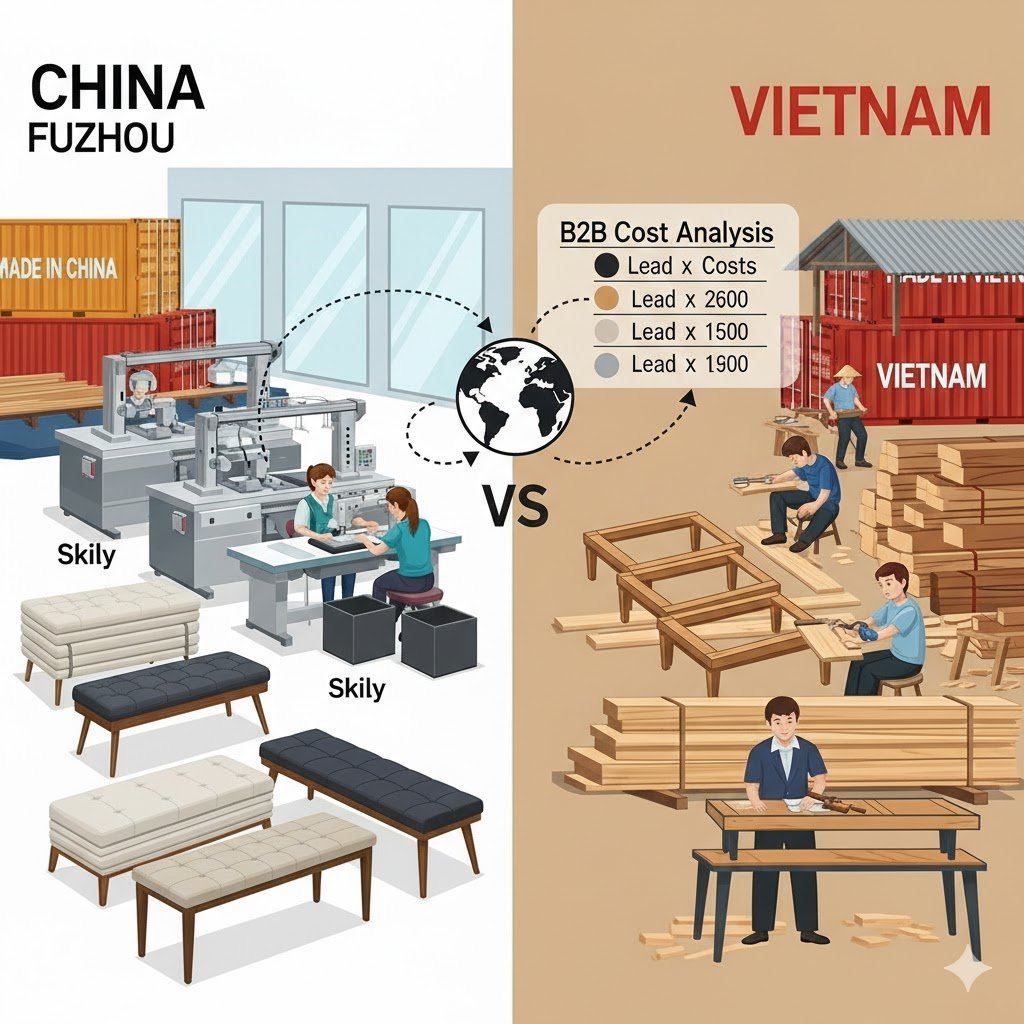

Breakdown of Storage Ottoman Manufacturing Costs: China vs. Vietnam

Insights for B2B Furniture Buyers on Sourcing Strategies and Cost Optimization.

1. Raw Material Sourcing (55-60% of Total Cost)

Raw materials represent the largest portion of manufacturing expenses. Whether you are sourcing a fringe upholstered ottoman or a standard linen bench, the origin of materials matters:

- China (Fuzhou Hub): Benefit from massive industrial clusters. We source premium fabrics directly from nearby suppliers, keeping material costs 5%-10% lower than in Vietnam.

- Vietnam Base: While Vietnam has local timber advantages, specialized upholstery materials are often imported, adding slight overhead to the initial production cost.

2. Labor Costs vs. Production Efficiency

Vietnam: Labor rates are approximately 50% lower than in China, making it ideal for large-scale industrial entryway bench production where manual assembly is high.

China: Higher wages are offset by 1.5x higher efficiency. Our Fuzhou artisans ensure lower defect rates for complex designs, which is a key reason why storage ottomans remain high-margin products for retailers.

3. Export Duties & Landed Cost Impact

For US buyers, the “Landed Cost” includes ocean freight and duties. We maintain transparency through our Live Container Loading Reports, showing how we maximize container space to reduce your per-unit shipping cost.

| Factor | China Origin | Vietnam Origin |

|---|---|---|

| US Section 301 Tariff | High (25%) | Exempt / Low |

Final Sourcing Verdict

Choosing between China and Vietnam depends on your target market and order volume. For more details on our manufacturing capabilities, visit our Contact Page to request a customized factory tour or price list.